Geotechnical Engineering For Construction Projects - Truths

Getting The Geotechnical Engineering For Construction Projects To Work

Table of ContentsExcitement About Geotechnical Engineering For Construction ProjectsHow Geotechnical Engineering For Construction Projects can Save You Time, Stress, and Money.What Does Geotechnical Engineering For Construction Projects Do?Geotechnical Engineering For Construction Projects Can Be Fun For AnyoneNot known Details About Geotechnical Engineering For Construction Projects

During the investigation, it is vital to drill at the called for depth and the required number of openings as per the suggestion of the Canadian Structure Style standard. Occasionally, the proprietor could conserve some Geotechnical Examination cost but wind up spending greater than the anticipated during the building price.The responsibilities of the geotechnical expert include offering product testing for construction support. Geotechnical Engineering for Construction Projects. Geotechnical designers evaluate all the field examination reports to make sure that construction is going on according to the task specification. During building and construction, a confirmatory test for soil compaction is done on-site to make certain that no future negotiation occurs

After the concrete is poured -7 days and 28 days- tests are carried out on concrete examples gathered from the site to guarantee that the concrete put meets the style standard. Asphalt core is taken after the Asphalt is laid and compressed to verify that it fulfills the style criterion. All research laboratory examination reports are analysed by the Geotechnical Designer to make certain that it meets the job spec.

The Ultimate Guide To Geotechnical Engineering For Construction Projects

Geotechnical engineering plays an essential role in guaranteeing the security of building and construction jobs. Geotechnical engineering is a crucial branch of civil engineering that focuses on understanding the behavior of earth materials, such as dirt and rock.

For a reliable structure and a smooth building procedure, depend give the know-how you require. Call to get professional guidance and geotechnical services customized to your following task.

Rumored Buzz on Geotechnical Engineering For Construction Projects

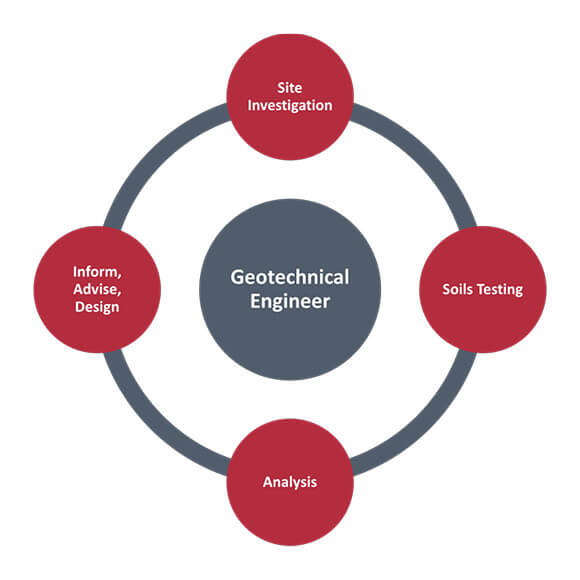

When starting a land advancement task, understanding the ground below your feet is as critical as the structures you intend to construct above it. Our Geotechnical Design group evaluate the ground, guaranteeing it is ideal for the recommended development while offering you with the details called for to fulfill your project goals.

Geotechnical Engineering takes a look at the development of the ground, as it is the structure obstructs for all jobs. Where structures need to be developed with regard to the ground conditions; ground problems (e.g., soft ground) might need strengthening depending upon the size of the designated framework. Before building, you need to find out about the groundwater, soil structure, and liquefaction likelihood of your land.

For websites that are not connected on the neighborhood authority framework additional site examinations would be needed to give technical inputs for on-site stormwater and wastewater. We have experienced Geotechnical Engineers based in each workplace, sustaining your geotechnical demands across the country. Connect to us to review how we can sustain your next project.

These records are customized to fulfill the certain demands of a task and include layout criteria and guidance for the construction of a variety of manufactured frameworks. In addition go to this web-site to providing working as a consultant services covering locations such as incline security and load-bearing abilities for various products, these engineers carry out r & d tasks to boost approaches, devices, products knowledge and evaluation covering whole lifecycles.

Unknown Facts About Geotechnical Engineering For Construction Projects

Nonetheless, rates of pay normally enhance as your understanding and skills expand, with standards aiming to a graduate beginning salary of between 18,000 and 28,000 annually in the UK. This rises to 26,000 to 36,000 with a couple of years of experience and afterwards reaching 40,000 to 60,000+ for elderly, chartered or master engineers.

However, with the appropriate application it is feasible to master the profession and gain access to a challenging yet rewarding and crucial occupation. A geologist would certainly need to re-train to become a geotechnical designer, although there is plenty of cross-over in between the two professions, which might make this simpler - Geotechnical Engineering for Construction Projects. Rock hounds require to have an understanding of dirts, rocks and other materials from a scientific point of view, while geotechnical engineers story their knowledge of issues such as dirt and rock visit our website technician, geophysics and hydrology and apply them to engineering and ecological jobs

When beginning, these engineers will often tend to deal with less complex tasks, accumulating understanding and experience prepared for more tough work later on. Geotechnical designers often tend to be experts in details locations as they expand in experience, concentrating on particular facilities such as railways, roads or water. These designers likewise deal with eco-friendly energy, offshore and onshore oil and gas, nuclear power, and more.

Get This Report about Geotechnical Engineering For Construction Projects

The time taken to come to be a geotechnical engineer depends on where you are based, where you research study and what degree of education you want to achieve before entering the office. Generally-speaking it takes 3-4 years to get to the fundamental requirements to begin a career as a geotechnical designer.

These operations make it possible for specialists to examine a host of soil mechanics consisting of weight, porosity, void-to-solid bit ratio, permeability, compressibility, optimum shear stamina, birthing ability and contortions. If the structure calls for a deep structure, engineers will certainly use a cone penetration useful content examination to approximate the amount of skin and end bearing resistance in the subsurface.

When evaluating an incline's equilibrium of shear anxiety and shear stamina, or its ability to withstand and undertake motion, rotational slides and translational slides are commonly taken into consideration. Rotational slides fall short along a rounded surface area, with translational slides happening on a planar surface. An expert's goal is to establish the problems at which an incline failure can take place.

Frequently, findings suggest that a site's soil must be treated to boost its shear strength, stiffness and leaks in the structure before style and building and construction. When it comes time to lay out structure plans, specialists are increasingly concentrated on sustainability, more particularly how to minimize a structure's carbon footprint. One technique has been to change 20 percent of a foundation's concrete with fly ash, a waste item from coal fire power plants.